Software Development vs. Manufacturing

The software creation world is viewed through two key paradigms: software development vs. manufacturing. These terms, while similar, represent different approaches. Software development is iterative, flexible, and creative, similar to an artist's work. In contrast, software manufacturing, like industrial production lines, focuses on efficiency and standardization. These differences highlight the evolving challenges and innovations in the software industry, and understanding them reveals emerging trends in software creation.

We can help you drive localization as a key initiative aligned to your business goals

Historical background

The historical background of software methodologies is deeply rooted in the influences of the industrial era and the subsequent adoption of these practices in the technology sector.

1. Influence of mass production

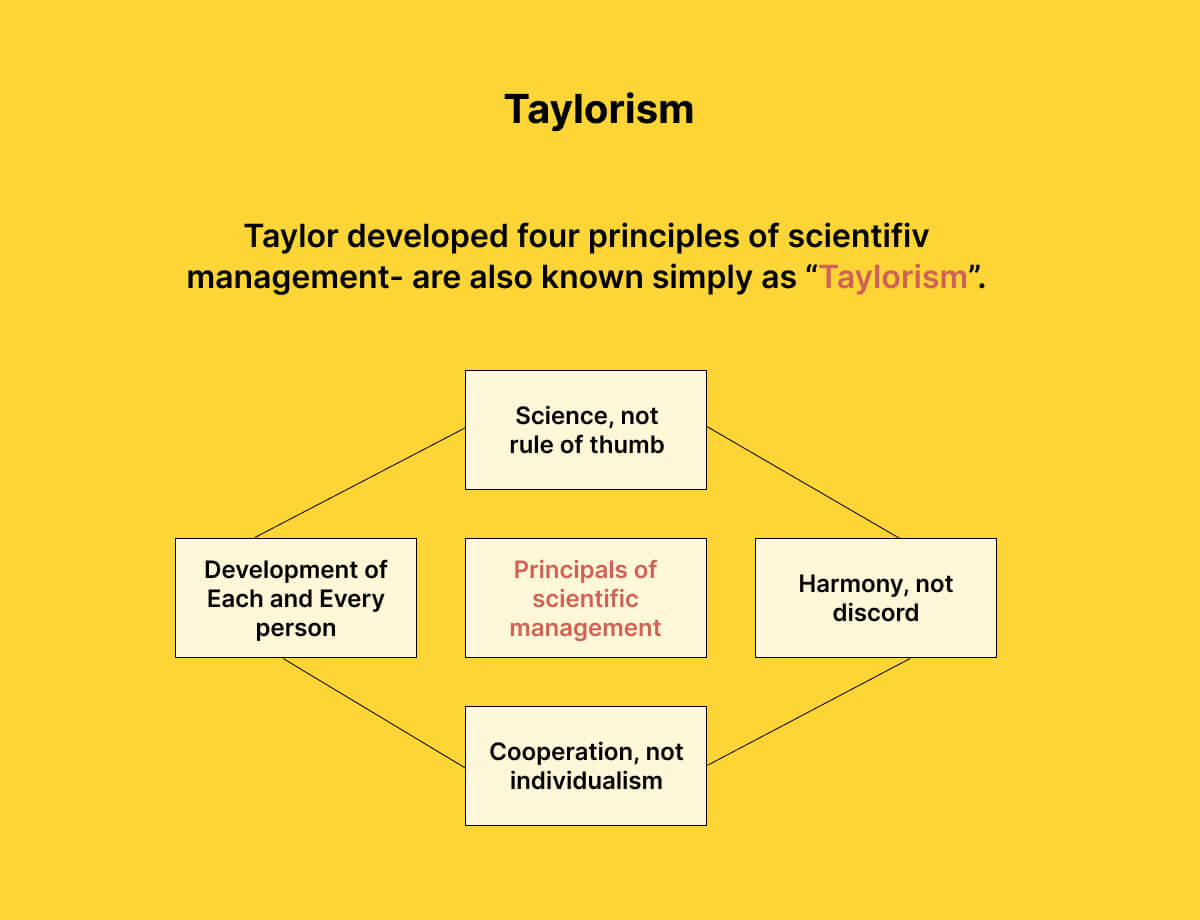

The industrial era brought forth revolutionary management theories and practices, notably Frederick W. Taylor's scientific management, also known as Taylorism.

Taylorism proposed a systematic approach to optimizing labor productivity and economic efficiency, treating workers as replaceable cogs in the industrial machine. This methodology, devoid of any consideration for the human element, laid the foundation for the Gantt chart by Henry Laurence Gantt. These tools and philosophies heavily influenced the management of labor and resources in manufacturing industries, from steel production to automobile assembly.

Transitioning from the industrial era's influence on manufacturing to its impact on the burgeoning field of software reveals a notable shift in methodologies.

2. The rise of Waterfall development in software

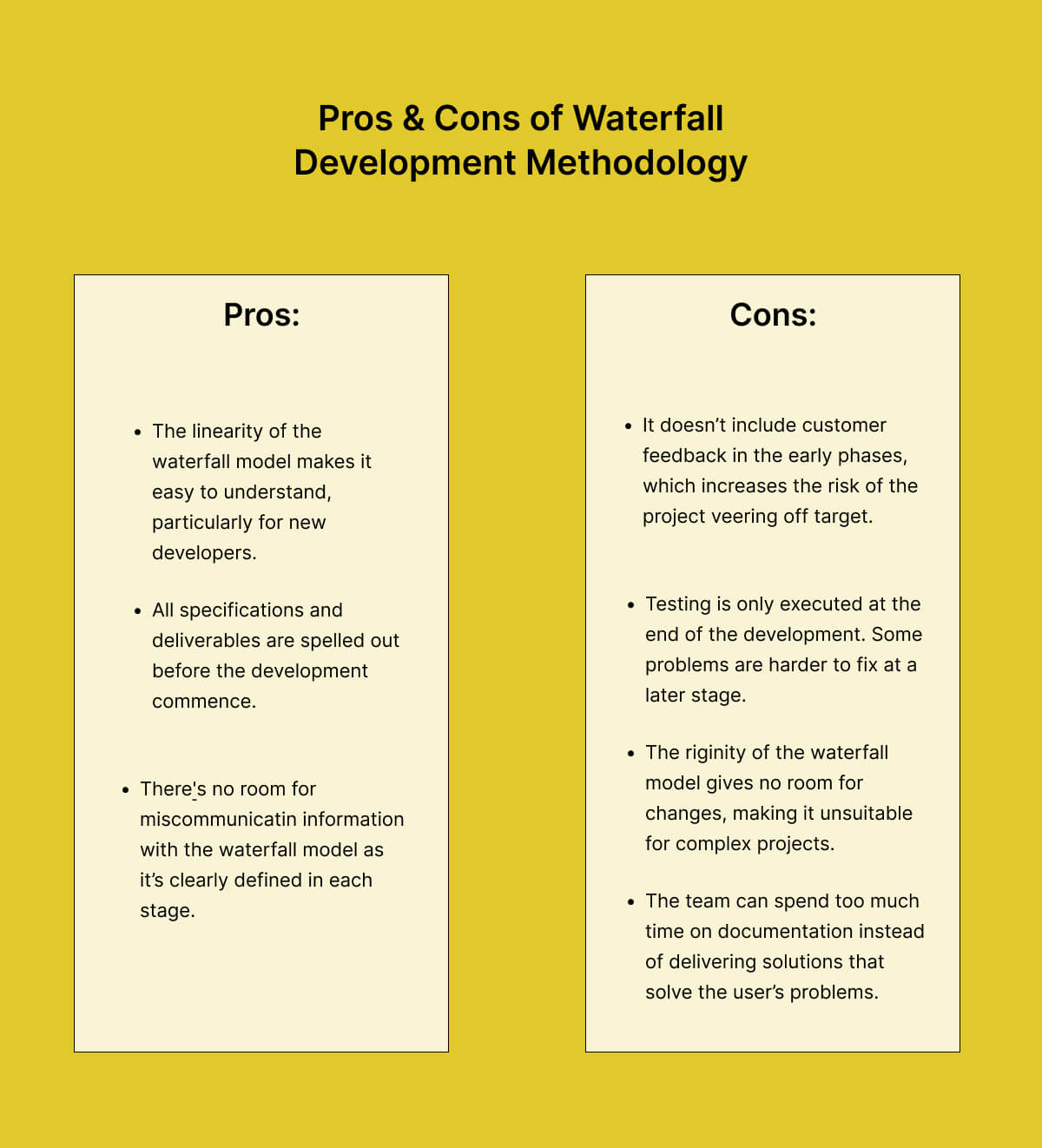

As the technology sector emerged and expanded in the 80s and 90s, the prevailing management styles from manufacturing were adopted almost unaltered. This led to the inception of the Waterfall development model in software, characterized by a linear and sequential approach. In this model, extensive planning, documentation, and rigid processes took precedence.

Under this regime, software development mirrored the factory floor - with managers and project leaders enforcing strict adherence to plans and schedules, often represented through Gantt charts.

The crisis in the software industry

The application of these manufacturing-based approaches to software development soon revealed its inadequacies. The CHAOS report by the Standish Group starkly highlighted the inefficiency of these practices, revealing a dismal success rate of just 16% for software projects. This crisis clearly indicated that the principles and practices effective in manufacturing were ill-suited for the software industry.

The nature of software development

The nature of software development is distinctly different from traditional manufacturing, emphasizing a design-centric approach and iterative processes.

1. Design phase vs. Production phase

Unlike traditional manufacturing, where design and production phases are distinct, software development is primarily design-centric. This is evident when comparing the development of a physical product, like a coffee mug, with software development. In physical product development, the production phase involves mass replicating the final design after finalizing the design through iterative prototypes and customer feedback. However, in software development, the 'production' phase has minimal cost and effort, focusing on continuous design and improvement.

2. The Iterative nature of software development

Software development thrives on iteration, experimentation, and constant feedback. The iterative process allows developers to continually refine and improve their products, adapting to changing customer needs and technological advancements. This approach starkly contrasts the rigid, linear progression of the Waterfall model.

The flaws of applying manufacturing principles to software

Applying manufacturing principles to software development reveals significant flaws, particularly when considering the unique nature of software projects.

1. Inadequacy of Taylorism in software

While effective in repetitive manufacturing environments, Taylorism's rigid, prescriptive nature hinders the creative and iterative process crucial to software development. Software projects needing innovation, adaptability, and responsiveness to changing requirements are ill-suited for Tayloristic methods. This approach leads to inefficiencies, stifled creativity, and often results in products that fail to meet the dynamic needs of users.

2. The myth of "Software manufacturing"

The concept of 'software manufacturing' implies a mechanical, repetitive process similar to a factory line. However, this view overlooks the fundamental nature of software development as a creative, intellectual, and iterative process. Unlike physical goods, the software can be replicated with virtually no cost, eliminating the need for traditional 'mass production.' The true challenge in software lies not in its production but in the ongoing development of valuable, effective, and user-centric solutions.

Modern approaches to software development

Modern approaches to software development have emerged in response to the limitations of traditional methods, focusing on flexibility, rapid iteration, and the human element.

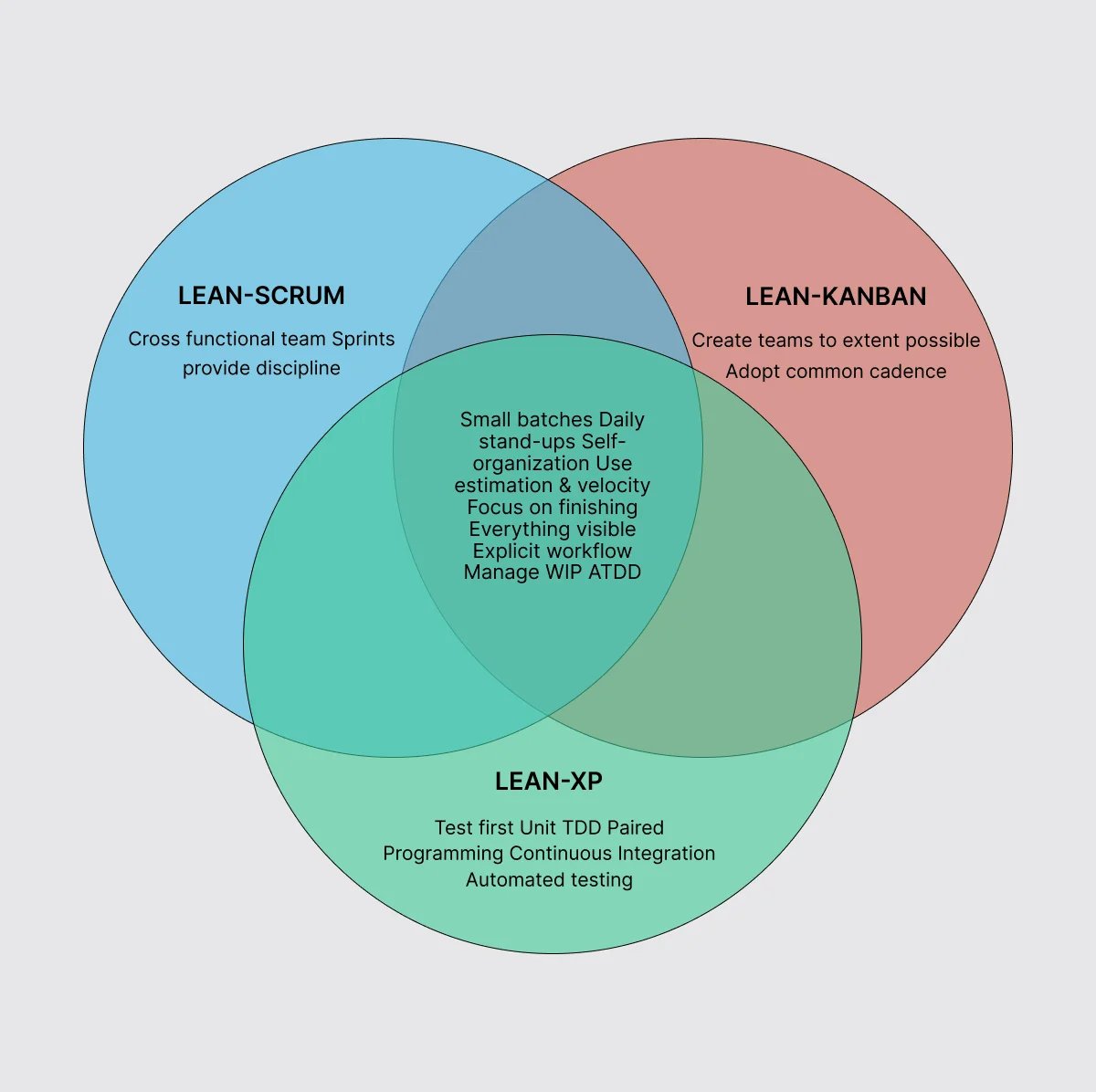

1. Agile, XP, Scrum, and Lean methodologies

The software industry experienced a significant shift with the introduction of Agile, Extreme Programming (XP), Scrum, and Lean methodologies. These approaches prioritize flexibility, rapid iteration, and close customer collaboration. They value working software and team collaboration over extensive documentation and rigid processes. These methodologies are more than just practices; they represent a mindset that values human creativity and adaptability to change.

Building on these methodologies, the role of the human element in software development takes on a central significance.

2. The human element in software development

At the heart of these modern methodologies is the view of software developers as skilled professionals, not mere cogs in a machine. This human-centric approach promotes communication, collaboration, and mutual respect. It recognizes that the best software solutions come from teams who understand their client's needs and are empowered to make informed decisions. This focus on the human element is a key differentiator in modern software development, enabling more effective and responsive solutions.

Case studies and real-world examples

The adoption of modern software development methodologies can be seen in the real-world transformations of major companies like IBM and Microsoft.

1. IBM's transition to Agile

Background: IBM historically used a traditional Waterfall approach in software development.

Transition: IBM shifted to Agile methodologies to stay competitive and respond swiftly to market changes.

Outcome: IBM's adoption of Agile led to improved team collaboration, quicker market entry, and better product quality. This case underscores the advantages of flexible, iterative approaches in large-scale software environments, demonstrating Agile's applicability beyond small projects.

2. Microsoft's adoption of DevOps

Background: Microsoft encountered issues with efficiency and coordination between development and operations.

Transition: By embracing DevOps practices, Microsoft effectively bridged the gap between its developers and operations teams, fostering a culture of continuous integration and delivery.

Outcome: This shift resulted in more regular updates, enhanced software quality, and a more agile development cycle. The evolution of the Azure cloud platform is a testament to the positive impacts of DevOps in streamlining and improving software development processes.

The challenge of changing mindsets

To fully appreciate the complexities and potential roadblocks in the evolution of software development practices, it's crucial to understand the challenges associated with changing organizational mindsets.

1. Limitations of mandating frameworks

Adopting modern methodologies in software development often faces the hurdle of shifting away from traditional management styles. A critical issue arises when frameworks like Scrum or SAFe are imposed top-down, which can inadvertently mirror the process-over-people approach of Taylorism.

True agility and lean thinking necessitate granting teams autonomy to determine their most effective working methods. The focus should be on resolving actual customer issues rather than strictly adhering to a particular framework. This approach encourages creativity and adaptability, which are essential for successful modern software development.

2. Leadership in software development

This paradigm shift also demands a transformation in leadership roles from being controllers to enablers. Leaders should act as facilitators and supporters in an Agile and Lean environment. Their role is to assist teams in removing obstacles and aligning resources with the teams' needs.

Embracing a servant-leadership model is pivotal in creating an environment conducive to innovation and maximizing customer value. Leaders must foster a culture of trust, open communication, and continuous learning to leverage the benefits of Agile and Lean methodologies truly. This shift in leadership style is integral to the successful adoption and sustainability of modern software development practices.

Key differences between software development and software manufacturing

The following differences highlight the contrasting philosophies and operational modes between software development and software manufacturing:

1. Process and flexibility

- Software development: Emphasizes an iterative, agile process. It's adaptable and responsive to changes and feedback throughout the development cycle.

- Software manufacturing: Follows a linear, structured approach akin to assembly line production. It's less flexible to change once the process is underway.

- Software development: Highly creative, encouraging innovation and experimentation. Solutions are often tailor-made for specific problems or needs.

- Software manufacturing: More focused on efficiency and standardization, potentially at the expense of creative solutions.

- Software development: Recognizes the importance of the human element. Collaboration, communication, and developer autonomy are key.

- Software manufacturing: Often views developers more as interchangeable parts of a process, with less emphasis on individual creativity.

- Software development: Encompasses the entire lifecycle of software, including continuous updates and improvements post-launch.

- Software manufacturing: More concerned with the production phase, focusing on efficiently replicating the software after the initial development.

- Software development: Agile and able to pivot or adapt based on user feedback or changing market conditions.

- Software manufacturing: Changes are more costly and difficult to implement once the process is set in motion.

Common ground between software development and software manufacturing

Despite their differences, there are areas where software development and manufacturing share common ground, reflecting their shared ultimate goals in software creation.

- Quality focus: Both software development and software manufacturing are committed to producing high-quality outputs. While their approaches to achieving this quality may vary, with development focusing more on adaptability and manufacturing on standardization, the goal of delivering a robust, reliable product remains a common objective.

- Efficiency goals: Both approaches, despite their differing methodologies, aim to produce software efficiently and cost-effectively. Software development achieves this through iterative processes and continuous improvement, while software manufacturing focuses on streamlined, repeatable processes.

- Use of technology: Advanced technologies and tools are fundamental to both software development and manufacturing. These include tools for development, testing, and deployment.

- Customer satisfaction: Ultimately, software development and manufacturing are driven by delivering products that meet user needs and requirements. Whether through tailored, innovative solutions in development or efficient, standardized production in manufacturing, customer satisfaction remains a central focus.

8 Future trends to keep an eye on

These trends indicate a future where the lines between development and manufacturing might blur, with an overall shift towards more agile, user-focused, and technologically advanced software creation practices.

1. Increasing emphasis on DevOps

Integration of development and operations to streamline the entire software lifecycle. This approach is increasingly being adopted to enhance efficiency, reduce time-to-market, and improve software quality.

2. AI and machine learning in development

Utilization of AI for code generation, predictive analytics, and automated testing. This trend is poised to revolutionize how software is developed and maintained.

3. Low-Code and No-Code platforms

The rise of platforms that allow for software creation with minimal coding, making development more accessible and speeding up the process.

4. Shift toward a microservices architecture

Moving from monolithic architectures to microservices for greater scalability, flexibility, and faster deployment.

5. Focus on cybersecurity

As threats evolve, there will be an increased emphasis on incorporating robust security measures during the software development process.

6. Sustainable software development

Greater awareness and initiatives towards developing environmentally sustainable software, considering factors like energy efficiency and resource utilization.

7. Remote and distributed teams

The growing trend of remote work will continue to influence how software development teams are formed and managed, focusing on tools and practices that support collaboration across distances, (such as Archie) a platform that streamlines team management and communication, making remote collaboration more efficient and productive.

8. User-centric design

Continued emphasis on user experience (UX) design, with more tools and methodologies focusing on creating user-centric software solutions.

Conclusion

The distinction between software development and software manufacturing is not just semantic but foundational. The software industry's journey from manufacturing-inspired methods to Agile and Lean practices reflects a deeper understanding of the unique nature of software development. It underscores the importance of embracing principles that value human creativity, flexibility, and continuous improvement. As the industry evolves, so must our approaches, always aiming to deliver valuable, effective, and user-centric software solutions.

How can Global App Testing help?

Global App Testing (GAT) can significantly aid in software development by providing various testing services and methodologies that align with modern development practices. Here's how GAT can be beneficial:

- The crowdtesting model involves a community of over 90,000 testers in 190 countries. This model allows for diverse and comprehensive testing across various real-world scenarios and environments, ensuring that software is robust and performs well globally.

- GAT supports Agile and DevOps methodologies by incorporating continuous testing practices. This aligns testing closely with ongoing development activities, enabling faster iterations and more efficient development cycles.

- Integrations with collaborative tools like Jira and Trello facilitate effective communication between testers and developers. Thus, testing is integrated smoothly into the development workflow and quickly addresses any issues.

- Commitment to high-security standards, which are crucial for software development, especially in sensitive industries.

- Scalable testing resources that can be adjusted according to the project's needs, providing comprehensive test coverage and quick feedback loops.

Are you interested in learning more about how we can help you deliver top-notch products?

Sign up, and let’s schedule a call today!

We can help you drive global growth, better accessibility and better product quality at every level.

Keep learning

How to create a test plan for software testing in 2025

10 Types of web application testing

Automated testing vs Manual testing - What's the difference?